ARC OFF – Improving the end of the weld in Liftig

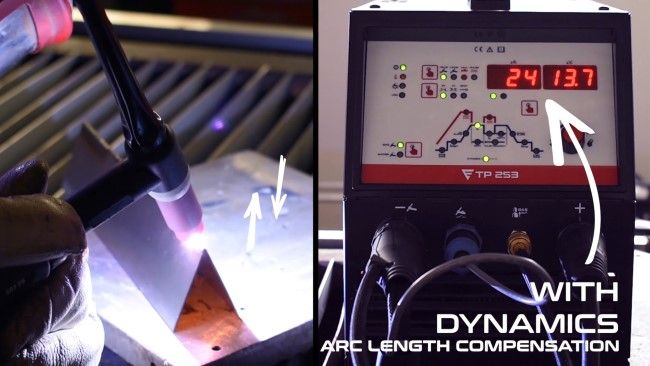

Problems at the end of the weld, when using tig with lift? We present video about ARCOFF function, which when the welding voltage value set by the operator is reached, the arc extinguishes automatically to improve the end of the weld. This function is available in all DC models of MMA/TIG serie3.