TIG pulsed welding

TIG pulsed arc welding is a variation of the TIG process, which switches between two levels: a peak current and a base current. Although this variant existed for several years, nowadays with electronic power control technologies we can achieve pulses per second (pulse frequency) much higher than those of a machine with conventional technology. For this, we need an inverter welding machine with pulsed Tig as such of the Electrex’s TP range (163, 203, 223, 253, 323, 403, 503 DC ou AC/DC).

PULSED TIG ADVANTAGES

This process allows the incensement of the quality of the welds, it reduces the costs of the process, obtaining narrower or wider arcs, it controls the temperature of the welding bath, it allows welding with more or less penetration or even reproduce the dimes effect more easily.

Besides these, allows:

- less heat input to the work piece, preventing the deformation of the work piece.

- an arc more concentrated, allowing more penetration.

- possibility of welding plates of different thicknesses

- More control of the welding bath.

PULSED TIG ADJUSTING PARAMETERS

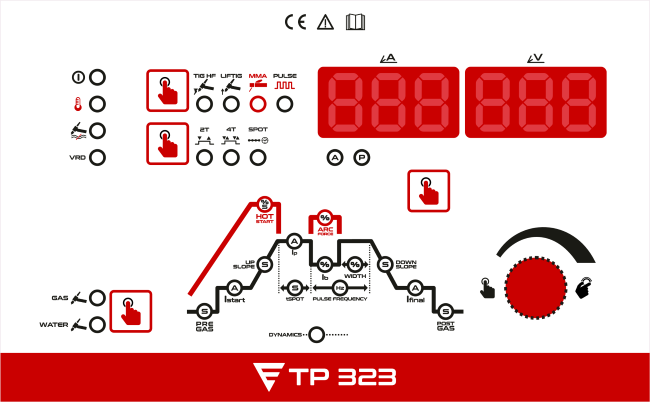

Take the example of ELECTREX TP 323, for regulating the pulsed parameters and its consequences in the welding process.

After selecting process of TIG welding and pulsed mode, we have 4 specific parameters that can regulate pulsed TIG:

Main Current (Amperes), the base current (Ampere), pulse frequency (Hz) and peak current ratio time / Base current time (%).

The main current or peak current is the current with higher intensity, while the base current is the current at a lower intensity. The welding current value is the average of the two currents levels.

The pulsed rate is represented by the number of cycles per second between 0.5 and 200 cycles per second.

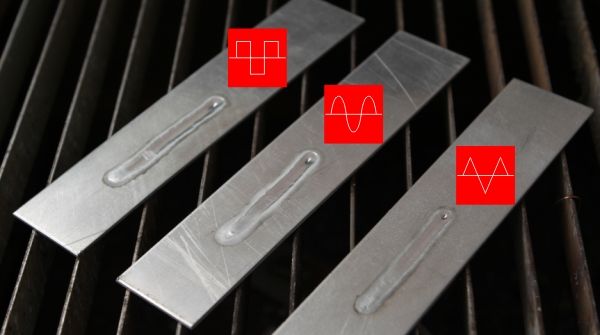

At a higher pulse rate corresponds to a more concentrated arc, producing narrower seams and decreasing the thermally affected zone.

The cadence of the dimes effect will also be proportional to the pulse frequency and a smooth seam with a very high pulse rate can also be obtained.

Finally, the pulse time or length can be adjusted at both current levels and the effects of pulse length identical to pulse rate can be adjusted.

The shorter the main current time, the lower the heat induction, there will be greater penetration and narrower seams will be obtained.