Author: electrex

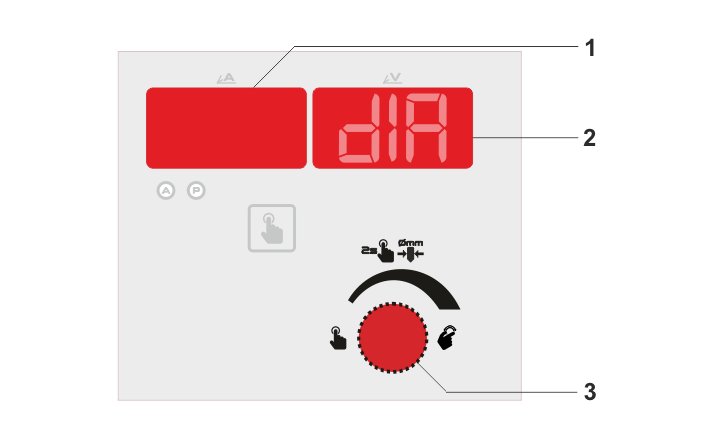

The Importance of Wires and Fluxes in Submerged Arc Welding (SAW)

Submerged Arc Welding (SAW) is widely used in industrial applications that demand high productivity, consistent quality, and efficiency. In this process, consumables such as wires and fluxes play a crucial role in ensuring the desired results. In this article, we explore the characteristics and importance of these components and how they can be optimized for different applications.

The Role of Wires in SAW

Wires used in submerged arc welding are responsible for depositing weld metal and forming the weld bead. They are available in various types and chemical compositions, which must be selected based on the base material and project specifications.

Common Types of Wires:

- Carbon Steel Wires: Used for welding common materials such as structural steel and pipelines.

- Stainless Steel Wires: Ideal for applications requiring resistance to corrosion and high temperatures.

- Low-Alloy Wires: Recommended for welding in extreme conditions, such as cold environments or high mechanical demands.

Factors to Consider When Selecting a Wire:

- Compatibility with the Base Material: The chemical composition must ensure uniform and strong welds.

- Wire Diameter: Depending on the thickness of the material being welded and the welding parameters.

- Performance Requirements: Properties such as crack resistance, ductility, and surface finish.

The Critical Role of Flux in SAW

Flux is a granular material that covers the electric arc and the weld pool during welding, providing protection from external contaminants and directly influencing the quality of the weld bead.

Benefits of Flux:

- Weld Pool Protection: Prevents porosity formation and improves weld integrity.

- Arc Stability: Ensures a consistent process and reduces spatter.

- Adjusting Chemical Composition: Can add elements to the weld bead to meet technical specifications.

The Synergy Between Wire and Flux

To achieve the best results, the combination of wire and flux must be carefully selected. Some fluxes are specifically designed to work with certain types of wires, maximizing productivity and ensuring optimal mechanical and metallurgical properties.

Technological Advances and Sustainability

With a growing focus on sustainability and efficiency, wire and flux manufacturers have invested in solutions that reduce waste and environmental impact. For example:

- Recyclable Fluxes: Reduce material consumption.

- High-Efficiency Wires: Minimize energy consumption.

Electrex’s Commitment

At Electrex, we offer a complete range of wires and fluxes for submerged arc welding, designed to meet the demands of the most challenging markets. We work closely with our customers to identify the best solutions for each application, ensuring quality, efficiency, and performance.

Conclusion

Wires and fluxes are critical components for the success of submerged arc welding. With the right selection and the support of specialists, it is possible to optimize processes, increase productivity, and guarantee high-quality welds. Get in touch with Electrex and discover how we can contribute to the success of your next SAW project!

Discover our offer for welding consumables where you can find our range of wire and flux for submerged arc welding by clicking here!

Kerllem – an inspiring story

On Women’s Day, we interviewed a female welder with an inspiring story: Kerllem Gonzaga Lopes, mother of 2 children who lives in a predominantly male world, but who claims that the profession of welder is not too heavy for a woman because “we do what we love ”.

She leaves some advice to women who want to enter the world of welding: “Know that there will be good and bad days and do it with love and dedication that everything goes well”.

Electrex: What motivated you to pursue a career as a welder?

Kerllem: The death of my husband and having two young children to support is what motivated me. But I already knew welding, because my father had a small truck body factory, but I started working directly with industrial welding only in 2008 with the death of my husband. Then I went to the professional level and then the story is very long. But as I usually say, it wasn’t me who chose welding, it was welding that chose me.

Electrex: A question we can’t escape: was it difficult for you as a woman to enter a mostly male world?

Kerllem: Kerllem: It wasn’t difficult for me because I was born and raised in a male environment. With my father and my two brothers, I always worked with them, and I always had among my father’s employees who were all men. For me, when I went to the industrial area, it didn’t make much difference, the environment was the same. My family was my base, my father, my brothers, my husband and my two children taught me to be who I am.

Electrex: How do people react when they ask you what you do and you say that you are a welder?

Kerllem: The reaction is always one of astonishment. “A female welder”. I always smile because they always say the same thing: it’s a very heavy man’s profession for a woman and I answer no because when we do what we love. It’s not heavy and I love my profession and I’m very grateful for everything.

Electrex: What advice would you give to young women who want to be welders?

Kerllem: Don’t give up at the first hurdle. Let them know that there will be good and bad days and do it with love and dedication that everything goes well. Welding is practical, we are learning every day and I am happy to have more women entering this profession.

Bending Service

Consult Electrex for bending services for any type of metal (sheets up to 2 meters and 4 mm thick)! Our specialized CNC bending operators have extensive experience and strict quality control. With adjustable stops, our service provides an increase in profitability and quality in bending dimensions.

Note: all bending service requests are made by our specialized budgeting team and depend on a previous study.

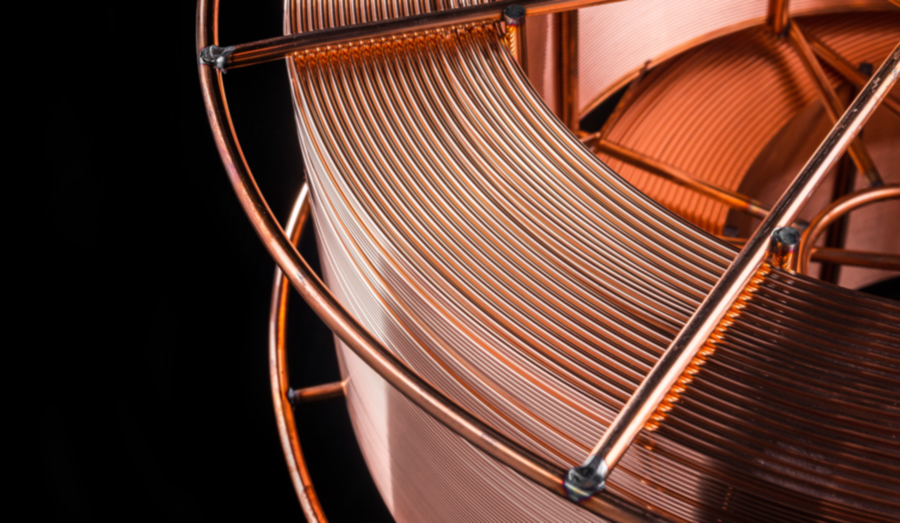

What’s new in TP AC/DC version 2?

The new version 2 AC/DC TIG welding machines are improved and equipped with several new functions. This article describes what’s new in version 2 compared to version 1 and guides you through some important adjustments you should make to get a better experience with these machines.

New features:

DYNAMICS

This function has been available in TP DC series and is now also available in TP AC/DC version 2. In TIG welding, it allows constant thermal delivery and can in certain cases be an aid to welders who do not have a trained “hand”. You can see a demonstration of this feature in this video:

PULSED MMA

Also available in the TP DC series and now in the TP AC/DC version 2, in this function, the current oscillates between two values (peak current and base current). Applications for this type of coated electrode welding vary, ranging from vertical up and overhead welding to less deformation on thin plates, greater arc control and better welding on gap plates.

TIG SPOT

The TIG SPOT function allows for maximum repeatability and perfection when making points with TIG welding. Set your TIG cycle, adjust spot time from 0.1 to 20 seconds and make perfect, and uniform points.

MANUAL PULSE

When the machine is set to 4T and non-pulsed TIG welding, the operator can switch between main current and base current and so on by quickly pressing and releasing the torch trigger.

JOBS

The JOBS function, memories to save and repeat your welding programs, is not new in version 2, but it has gone from 9 available memories (version 1) to 20 (version 2), allowing the operator to have more room for maneuver.

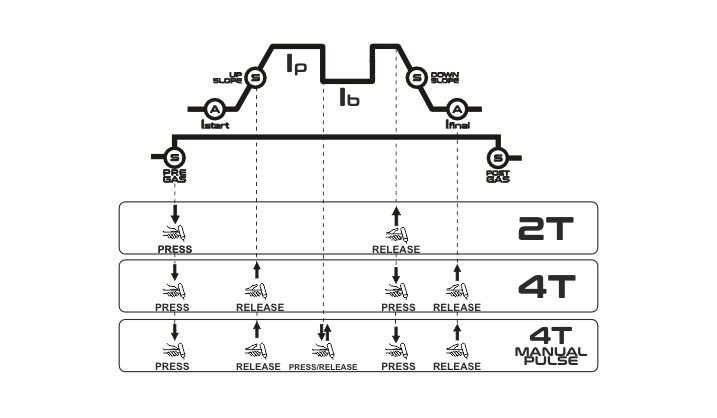

ARC IGNITION

TIG arc ignition has been improved in version 2. To optimize arc ignition, the operator will have to define the tungsten electrode thickness in advance. It is an important adjustment that will greatly affect the quality of the welding work. Therefore, we transcribe a part of the instruction manual:

– Press button 3 for 2 seconds until display 2 shows dIA. Turn knob 3 to select the appropriate tungsten electrode diameter (values 1.0, 1.6, 2.4, 3.2 or 4.0 mm are shown on display 1).

ERROR 6

In version 2, a new error was introduced (Er6) where the machine automatically detects the lack of phase of a certain electrical installation and alerts the operator.

These are the main features that the user must consider in their welds. In addition, the machine has been improved and optimized internally, namely in the high-frequency module and in the control module.

Comparison of Electrex MIG/MAG welding machines

Electrex has several and different options when it comes to MIG/MAG welding machines: Inverter or conventional power source? Electronic or step control? Standard or pulsed? And we could continue with more options. In this article we try to clarify the different lines of Electrex MIG/MAG welding machines: DIGIT II, SYNERGIC II, LTRONIC SYNERGIC, MULTI BASIC and MULTI PULSE.

The most striking difference is the type of power source. The DIGIT II, SYNERGIC II and LTRONIC SYNERGIC lines are based on transformers and the MULTI BASIC and MULTI PULSE lines are with inverter technology. Transformer-based ones allow them to be more accessible in terms of purchase price, but at the same time have more weight and volume, while inverters allow for better energy consumption, low weight and compact design.

Regarding the control, on the DIGIT II and SYNERGIC II the welding voltage regulation is carried out by switches, and the regulation is stepwise. On LTRONIC SYNERGIC, the welding voltage is regulated by thyristors, allowing for continuous adjustment. Finally, on MULTI BASIC and MULTI PULSE, just like LTRONIC SYNERGIC, regulation is carried out electronically, but these through modulation of transistors switching. This allows for a more stable and accurate welding arc.

DIGIT II, SYNERGIC II and LTRONIC SYNERGIC welding machines only allow one welding process, ie they only allow MIG/MAG welding. As the name implies, MULTI BASIC and MULTI PULSE allow, in addition to the MIG/MAG process, coated electrode welding (MMA) and TIG welding (with contact ignition). Therefore, they are multi-process.

SYNERGIC II, LTRONIC SYNERGIC and MULTI PULSE allow welding using synergistic programs, ie welding programs adjusted at the factory and optimized for different metals such as steel, stainless steel and aluminum.

Regarding pulsed MIG/MAG welding, only the MULTI PULSE line offers this type of welding, which is a variant of MIG/MAG, allowing for thin plate welding, almost without projections and out-of-position welding.

Discover our MIG/MAG welding machine lines:

TIG pulsed welding

TIG pulsed arc welding is a variation of the TIG process, which switches between two levels: a peak current and a base current. Although this variant existed for several years, nowadays with electronic power control technologies we can achieve pulses per second (pulse frequency) much higher than those of a machine with conventional technology. For this, we need an inverter welding machine with pulsed Tig as such of the Electrex’s TP range (163, 203, 223, 253, 323, 403, 503 DC ou AC/DC).

PULSED TIG ADVANTAGES

This process allows the incensement of the quality of the welds, it reduces the costs of the process, obtaining narrower or wider arcs, it controls the temperature of the welding bath, it allows welding with more or less penetration or even reproduce the dimes effect more easily.

Besides these, allows:

- less heat input to the work piece, preventing the deformation of the work piece.

- an arc more concentrated, allowing more penetration.

- possibility of welding plates of different thicknesses

- More control of the welding bath.

PULSED TIG ADJUSTING PARAMETERS

Take the example of ELECTREX TP 323, for regulating the pulsed parameters and its consequences in the welding process.

After selecting process of TIG welding and pulsed mode, we have 4 specific parameters that can regulate pulsed TIG:

Main Current (Amperes), the base current (Ampere), pulse frequency (Hz) and peak current ratio time / Base current time (%).

The main current or peak current is the current with higher intensity, while the base current is the current at a lower intensity. The welding current value is the average of the two currents levels.

The pulsed rate is represented by the number of cycles per second between 0.5 and 200 cycles per second.

At a higher pulse rate corresponds to a more concentrated arc, producing narrower seams and decreasing the thermally affected zone.

The cadence of the dimes effect will also be proportional to the pulse frequency and a smooth seam with a very high pulse rate can also be obtained.

Finally, the pulse time or length can be adjusted at both current levels and the effects of pulse length identical to pulse rate can be adjusted.

The shorter the main current time, the lower the heat induction, there will be greater penetration and narrower seams will be obtained.

ARC OFF – Improving the end of the weld in Liftig

Problems at the end of the weld, when using tig with lift? We present video about ARCOFF function, which when the welding voltage value set by the operator is reached, the arc extinguishes automatically to improve the end of the weld. This function is available in all DC models of MMA/TIG serie3.

TIG Dynamics

TIG Dynamics, present in all serie 3 TP DC machines. It allows that, when there is a variation of the distance between the TIG welding torch and the workpiece, there is a compensation in terms of power of the machine to maintain the same thermal delivery.

Isabel Ferreira – welder by profession

“I had no problem integrating in a masculine environment, in fact in uniform we are all the same”

We took the Women’s Day to interview a female welder. Isabel Ferreira is a female professional welder in a metal workshop in Viana do Castelo, Portugal, who claims to have the privilege of doing what she likes.

Electrex: What motivated to take the Welding Technician course?

Isabel Ferreira: My father was a welder, and hence my interest since I was very little in this area.

Electrex: A question we cannot escape: Was it difficult for you as a woman to enter a mostly male world?

Isabel Ferreira: While I did the course no. But, for me, my biggest obstacle was when I looked for an internship and companies closed doors for not being prepared to receive women, I speak at the level of conditions, there are no women’s balnearies. When I got an internship, I can say that I was very well received and I had no problem integrating in a masculine environment, in fact in uniform we are all the same.

Electrex: What’s the reaction of people when they ask you about the profession and you answer that you’re a welder?

Isabel Ferreira: Most people are amazed, others ask me if I’m not afraid breaking my nails (laughs). Others, as they know my father was a welder, say that he must be proud to have followed his footsteps. It is normal for people to have these reactions, in Portugal the mentalities are still very closed.

Electrex: What advice would you give to young women who want to be welders?

Isabel Ferreira: I think that if women really want to follow this area, they must take a change, regardless of what other people might think or say. The best thing that happened to me was getting to work in this area feel fulfilled. Many people get up in the morning and it seems that they will be annoyed to work, I am glad because I joined the useful to the pleasant.

COLWIRE (Cold Wire) – TIG welding wire feeder

TIG welding feeder that allows the addition of wire over the bath

with tig welding intermittently or continuously. Reduce costs with addition material thanks to the lack of material waste, productivity gain and quality due to a consistent and fast material addition, faithfully reproducing the movement of the welder’s hand.

Suitable for manual, automatic or

orbital TIG welding applications on thin or thick metalsheets, pipes and refill. Suitable for steel, stainless steel

aluminium alloys, titanium, from 0.8 to 1.2 mm, in 5kg,15 kg spool or large wire packs.