What’s new in TP AC/DC version 2?

The new version 2 AC/DC TIG welding machines are improved and equipped with several new functions. This article describes what’s new in version 2 compared to version 1 and guides you through some important adjustments you should make to get a better experience with these machines.

New features:

DYNAMICS

This function has been available in TP DC series and is now also available in TP AC/DC version 2. In TIG welding, it allows constant thermal delivery and can in certain cases be an aid to welders who do not have a trained “hand”. You can see a demonstration of this feature in this video:

PULSED MMA

Also available in the TP DC series and now in the TP AC/DC version 2, in this function, the current oscillates between two values (peak current and base current). Applications for this type of coated electrode welding vary, ranging from vertical up and overhead welding to less deformation on thin plates, greater arc control and better welding on gap plates.

TIG SPOT

The TIG SPOT function allows for maximum repeatability and perfection when making points with TIG welding. Set your TIG cycle, adjust spot time from 0.1 to 20 seconds and make perfect, and uniform points.

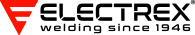

MANUAL PULSE

When the machine is set to 4T and non-pulsed TIG welding, the operator can switch between main current and base current and so on by quickly pressing and releasing the torch trigger.

JOBS

The JOBS function, memories to save and repeat your welding programs, is not new in version 2, but it has gone from 9 available memories (version 1) to 20 (version 2), allowing the operator to have more room for maneuver.

ARC IGNITION

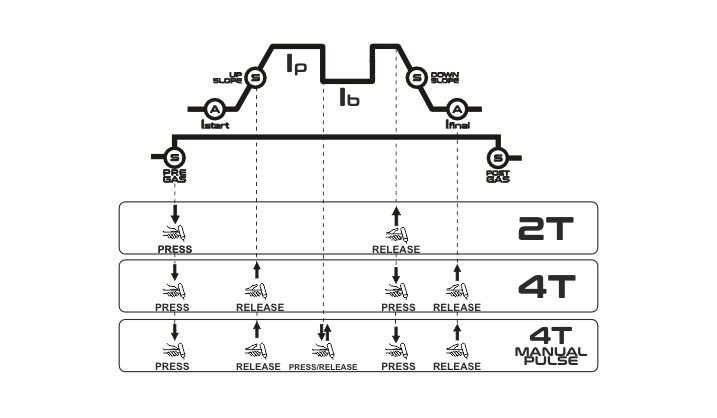

TIG arc ignition has been improved in version 2. To optimize arc ignition, the operator will have to define the tungsten electrode thickness in advance. It is an important adjustment that will greatly affect the quality of the welding work. Therefore, we transcribe a part of the instruction manual:

– Press button 3 for 2 seconds until display 2 shows dIA. Turn knob 3 to select the appropriate tungsten electrode diameter (values 1.0, 1.6, 2.4, 3.2 or 4.0 mm are shown on display 1).

ERROR 6

In version 2, a new error was introduced (Er6) where the machine automatically detects the lack of phase of a certain electrical installation and alerts the operator.

These are the main features that the user must consider in their welds. In addition, the machine has been improved and optimized internally, namely in the high-frequency module and in the control module.